What are the components of the starter of the hydraulic forklift?

Whether it is an hydraulic forklift or a diesel forklift, the starting system is very important. The starting system of hydraulic forklift consists of starter, starting switch and starting relay. Among them, the starter is the most important. Its function is to convert the electric energy of the battery into mechanical torque, and transmit it to the flywheel of the engine to drive the crankshaft of the engine to rotate. Its role sounds abstract and complex, and it doesn't matter if enterprises and drivers don't understand it. The following parts in the starter are very important for the electric forklift manufacturer.

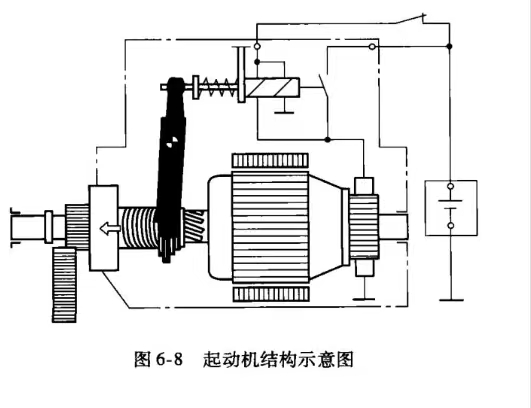

In general, the starter of hydraulic forklift consists of motor, transmission device and control device. The motor is mainly responsible for generating torque, which is composed of magnetic field, armature and brush. The current and torque of the starter are large, so the working time is very short, only 5~10s. Therefore, the electric forklift manufacturer tells us that its quality must pass the standard, and the enterprise and driver must choose the starter with high mechanical strength and low resistance.

The transmission device of the hydraulic forklift is mainly responsible for meshing the driving gear with the flywheel ruler ring when starting, and transmitting the starter torque to the engine crankshaft. After starting, make the starter and flywheel ruler ring separate automatically to prevent the starter from overspeed rotation driven by the generator. It is mainly composed of driving gear and one-way clutch. The electric forklift manufacturer told us that there are driving gears, internal and external raceways, rollers, springs, spline sleeves, fork sliding sleeves and buffer springs in the one-way clutch.

The operating device of the hydraulic forklift consists of an electromagnet mechanism, a motor switch and a fork pulling mechanism. The electromagnet mechanism is mainly responsible for the engagement and separation of the drive gear of the one-way clutch and the flywheel of the engine with electromagnetic force, and controlling the connection and disconnection of the motor switch. The motor switch is located in the front of the electromagnet mechanism, and its role is understood. The electric forklift manufacturer will tell you about the fork pulling mechanism. Its copper sleeve is equipped with a fixed iron core and a movable lead iron. The tail of the lead iron is rotationally mounted with a link rod and connected with the upper end of the fork, so that when the coil is energized, the lead iron drives the fork to swing around its axis, pushing out the one-way clutch, so that it engages with the flywheel ring gear.

The above is the basic structure and introduction of hydraulic forklift starter. Because space is limited, it is just a brief introduction. Enterprises and drivers who need to know more can consult the electric forklift manufacturer.

评论

发表评论