Is it more suitable for agv forklift in the hot summer?

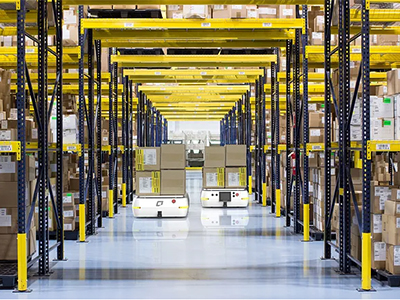

In the hot summer, employees in various positions in the company are insisting on their positions, and the most difficult one is the loading and unloading work, right? As a loading and unloading worker, I work early every morning, and the goods out of the warehouse need to be transported out of the warehouse by an electric forklift. The conditions allow the forklift to be directly loaded onto the truck. If the conditions do not permit, you need to manually load the goods on the forklift onto the truck. The goods in the warehouse need to be loaded onto the warehouse with a forklift.

The warehouse yard is generally made of concrete floors, and the sun’s heat is steaming. At this time, the loading and unloading workers are sweating like rain, and the heat is unbearable. Most companies only install large fans in the warehouse to prevent heatstroke. However, the effect of such weather is very small. The cooling effect is almost zero.

The hot weather and the shortage of human resources have brought a certain amount of pressure to the enterprise. So is there any way to deal with it? In fact, you only have one agv forklift.

Four advantages of forklift agv instead of labor:

1. Cost saving, AGV can work around the clock, and workers need to work 8-10 hours a day. In some aspects of product production, 100 people were originally required to operate. After the robot is replaced, only 1-2 people are required to monitor and execute in the background, and the work efficiency is much higher than that of manual work.

2. Easy to supervise employees. In the past, there were at least one hundred people in one workshop of a company. Many employees are always lazy without supervisor supervision. However, there are blind spots and corners in supervisors and equipment, which not only lead to the fluke of lazy personnel. Psychology spreads this fluke psychology to the entire team. After using AGV, the number of employees is greatly reduced, and the management of employees is also much more convenient.

3, the output is stable and efficient. The working cycle of the AGV is fixed. In other words, the production time of each product is also fixed. This effect cannot be achieved manually, and the output will fluctuate. The use of AGV can not only stabilize the output, but also increase the output of the product, which is more in line with the interests of the enterprise.

4. High employee safety. The use of AGV for operation and production can not only prevent work-related accidents caused by personnel, but also use AGV for operation with higher accuracy and safety.

In addition to the above 4 points, the more obvious advantage of summer is to avoid high temperature work for employees, which can cause irreversible consequences to the body.

评论

发表评论