How to solve the problem that the electric forklift cannot be started

Electric forklift can't walk

1. First check the forklift battery of the electric forklift to see if there is voltage. If there is voltage, check whether the voltage can be used normally. Repair method: If the battery has no voltage or the voltage is too low, charge the battery directly.

2. Check whether the lifting switch and circuit of the lifting accessories of the electric forklift are loose or short-circuited, and whether the micro switch is damaged. Repair method: repair and clean the circuit, replace or repair the micro switch.

3. Check whether the lifting contactor assembly of the electric forklift is burnt out or whether the coil is short-circuited or disconnected. Repair method: repair the platinum contacts of the contactor or directly replace with a new hydraulic contactor assembly.

4. Check whether the lifting module of the electric forklift is burned out or short-circuited or disconnected. Repair method: repair or replace the module assembly.

5. Check whether the hydraulic motor of the electric forklift has voltage, check whether the motor has short circuit or open circuit leakage, and check whether the carbon brush is severely worn. Repair method: repair the circuit, replace the carbon brush of the motor and repair the copper head of the motor, repair the hydraulic motor assembly or replace with a new hydraulic motor.

6. Check whether the hydraulic pump, multi-way valve, oil pipe, and oil cylinder of the electric forklift are damaged. Repair method: check and repair the hydraulic pump of the electric forklift or directly replace with a new hydraulic pump assembly. If the multi-way valve is damaged, repair or directly replace the new multi-way valve assembly, directly replace the new hydraulic oil pipe, and replace the oil cylinder. Repair the kit or replace the cylinder assembly with a new one.

7. The electric part of the electric forklift is faulty. Suddenly it did not advance or retreat, and there was no response. The forklift moves with one punch and one punch, and the forward speed cannot be adjusted.

Extended knowledge: How to troubleshoot problems with the steering system of electric forklifts?

When there is a problem with the steering system, you need to perform a preliminary inspection. You must first understand the situation. Don't rush to remove the steering gear. It should be a component that needs to be checked later. In the steering system, there are many other components. Cause a malfunction, so check other parts first.

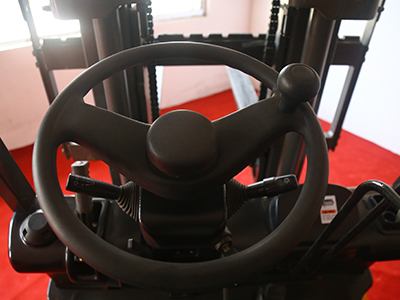

First, check the steering wheel and tires of the electric forklift. When the steering gear is disengaged, whether the steering wheel and wheels rotate flexibly and without resistance, whether the tire size is appropriate, and whether there is damage. Then check the installation angle of the steering wheel of the electric forklift, that is, the front wheel positioning angle, check whether the tie rod system is abnormally loose or tight, and then check the ball joint and king pin. The next step is to check other places that have been replaced before, such as repairing the replaced tubing, whether the direction of the tubing is wrong, or whether the diameter of the replaced tubing is too small, and other restrictive factors. If this happens, you need to rearrange the twisted and bent tubing and replace the tubing that is different from the original state. The last step is to check the oil storage tank of the power steering of the electric forklift to ensure that the oil reaches the correct level, check the pump drive belt, and adjust the belt according to the parameter requirements.

评论

发表评论