Parts that are prone to problems in manual forklift

The main accessories in manual forklifts are: handles, cylinders, valve bodies, wheel frames, push rods, brackets, oil seals, axles, bearings, wheels, etc. The main components that often have problems are the following.

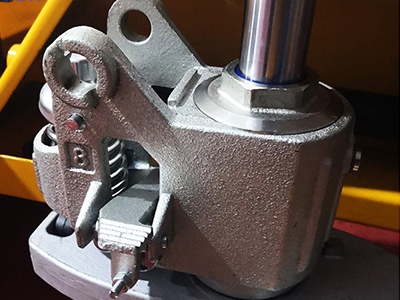

Pallet truck oil pump: The oil pump is a key component of all manual forklift. Once the oil pump has a problem, it means that the pallet truck is announced to stop working. No matter how good the other parts are, it is useless. Work is impossible. The oil pump is composed of many parts. Among them, dust-proof rings, O-rings, steel balls and other accessories are most prone to problems. The quick and easy solution is to replace these accessories. 2. Oil cylinder: The oil cylinder plays a vital role in the entire lifting process of the manual forklifts, and is also used to realize the lifting of goods.

If the fork of a manual forklift cannot be lowered or raised, the reasons: 1. The piston rod and cylinder may be damaged due to overload or unbalanced load during loading; 2. The piston rod is exposed and rusted for a long time, which hinders the smooth movement of the piston; 3 , The adjustment nut and the hexagonal nut are in the wrong position; at this time, replace the piston rod or cylinder according to the judgment, lower the forklift to the lowest level when not in use, and re-adjust the nut.

manual forklift oil seal: The oil seal is a key component between the piston rod of the oil cylinder and the cylinder barrel, and is generally equipped with an imported sealing ring. Mainly because of good sealing performance, wear resistance and long service life. And 70% of the oil leakage of the cylinder occurs on the oil seal. If oil leakage is found in the cylinder, it should be checked in time. If the sealing ring is aging or damaged, replace it with a high-quality sealing ring.

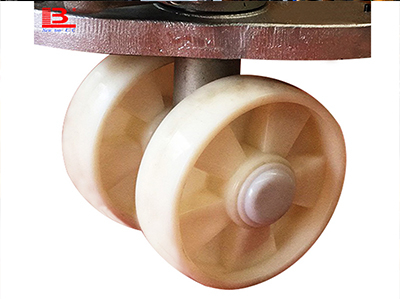

Pallet truck wheels: Wheels are a kind of wear, which will wear out after a long time. There are many types of pallet truck wheels, including nylon wheels, PU wheels, polyurethane coated nylon, rubber wheels, bakelite, etc. Most trucks are equipped with nylon wheels because they are common in the market and inexpensive, but they are less worn and noisy when traveling. Please replace the transport wheel in time if it is worn to a certain extent, the expensive one, the cheap one, the customer chooses. The one-piece wheel frame is equipped with dual front wheels, which has strong carrying capacity; the front and rear guide wheels are installed to protect the front wheels from impact and prolong the service life of the wheels. The standard configuration of handling wheels is polyurethane wheels. Nylon wheels and rubber wheels are optional. Nylon wheel features: low friction coefficient, high pulling noise, and ground abrasion. Polyurethane wheel features: low friction coefficient, low sound when pulling, and does not hurt the ground. Rubber wheel features: no damage to the ground, low sound when pulling, poor carrying capacity, not suitable for use when it exceeds 2.5 tons.

manual forklift lever frame: The lever frame is a key component connecting the oil pump and the push rod. The lifting support of the hydraulic cylinder, the handling and loading of goods are supported and balanced by the lever frame. Due to the possible occurrence of overload, unbalanced load, etc., it will often cause the lever frame to deform or break. It must be because the forklift is not operating normally. Find a forklift manufacturer or find a nearby market to replace the lever frame by yourself.

评论

发表评论