Development of storage system automation

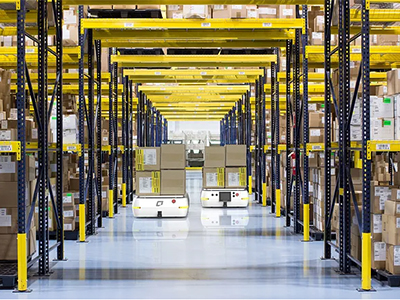

At this stage, intelligent warehousing has become a trend. The automation of warehousing system not only needs the intelligence of warehousing management system, but also needs the intelligent upgrading of warehousing equipment. At present, the common electric stacker in the market still stays in the traditional manual operation. Electric storage and handling equipment has developed from manual stacker to semi electric stacker, and then to the current electro-hydraulic forklift to the later AGV carrier. Electric forklift manufacturers are also trying to adapt to the development of the market.

What type of hardware configuration is generally required to realize warehouse system automation? It mainly includes: shelf, storage platform, conveying equipment, stacking equipment, automatic sorting system and automatic warehouse. electric stacker is one of the important storage equipment in the warehouse.

Warehouse platform is a place set up for loading and unloading goods by truck or truck. The warehouse in / out platform and loading / unloading system are the fixed facilities connecting various transportation vehicles in the warehouse, and they are important links to realize the automatic and efficient operation of the warehouse system. Conveyor is a mechanical equipment that continuously and evenly transports goods and packaged goods from the loading point to the unloading point along a certain route.

Electric stacker is the most important transportation, loading and unloading equipment in the automation process of storage system.

The automatic sorting system in the automation of storage system has high sorting capacity and high sorting speed, and can handle a variety of goods. At present, it is mainly used for the sorting of postal parcels, as well as the sorting of circulation and commercial logistics centers and distribution centers.

The automatic three-dimensional warehouse in the automation of storage system is composed of high-rise shelf, lane stacker (track stacker), incoming and outgoing material conveying system, automatic control system, computer storage management system and its peripheral equipment, which can realize the automation of container unit cargo storage and storage.

The automation of storage system has made a qualitative leap in the work efficiency of enterprises. Whether in terms of environmental protection, labor cost saving or other aspects, intelligent warehousing is commendable and meets the needs of the times.

评论

发表评论