How to maintain the new small electric forklift in autumn?

After the hot summer, the temperature gradually dropped and the climate changed significantly. In summer and autumn, small electric forklifts should pay special attention to maintenance during use. This season, the maintenance of small electric forklifts should do the following:

1. External maintenance of small electric forklift

There is more dew in the morning and evening in autumn, and the surface of small electric forklifts is often very humid. If there are obvious scratches on the body of the small electric forklift, it should be painted in time to prevent the scratched parts from getting damp and rusty. Due to the corrosion of rain acid in summer rain and the direct irradiation of strong light in summer, the painted surface of the small electric forklift body will inevitably be oxidized. When the season changes, it is best to clean and repair the surface of the small electric forklift.

2. Tire maintenance of small electric forklift

In the safe driving of electric counterbalanced forklifts, tires play a pivotal role. In summer, due to the high temperature, it is necessary to frequently check the tire pressure of the electric counterbalanced forklift. The tire pressure should not be too high, otherwise there will be a risk of a tire burst. In autumn, due to the relatively low temperature, the tires of electric counterbalanced forklifts need to be supplemented with air pressure to keep them within the specified air pressure range. At the same time, check the electric balance forklift tires for scratches, because the rubber is easy to harden and become brittle in autumn and winter, and the tires are easy to leak or even blow. Tires, always clean up the inclusions in the tire pattern.

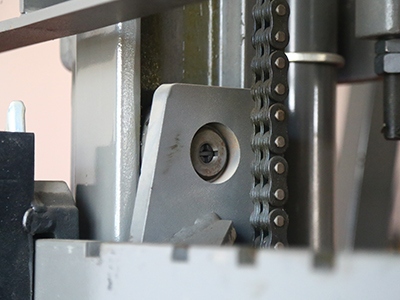

3. Maintenance of small electric forklift brake system

The large temperature difference between day and night in autumn is likely to cause the expansion and contraction of the body part of the electric counterbalanced forklift. It is necessary to check whether the brake of the electric counterbalanced forklift is weakened or deviated, and whether the pedaling force of the brake pedal of the electric counterbalanced forklift has changed. If necessary, clean the pipeline part of the entire brake system of the electric counterbalanced forklift.

4. small electric forklift battery maintenance

small electric forklift battery electrode wiring is the most prone to problems. During the inspection, if there is green oxide at the electrode wiring of the small electric forklift, it must be cleaned in time. These green oxides can cause small electric forklifts. Insufficient power of the generator will cause the battery to be scrapped in severe cases.

评论

发表评论